سعر فوب

أحصل على آخر سعر8000 ~ 49200 USD / Set

|1 Set Minimum Order

بلد:

China

نموذج رقم:

BP-8177-ZB

سعر فوب:

8000 ~ 49200 USD / Set أحصل على آخر سعر

الموقع:

China

سعر الحد الأدنى للطلب:

8000 per Set

الحد الأدني للطلب:

1 Set

تفاصيل التغليف:

Plywood Wooden Case

موعد التسليم:

20 days

القدرة على التوريد:

100 Set per Month

نوع الدفع:

Other, PayPal, Western Union, T/T

مجموعة المنتج :

الشخص الذي يمكن الاتصال به Ms. May

Dongguan, Guangdong

Product

description

|

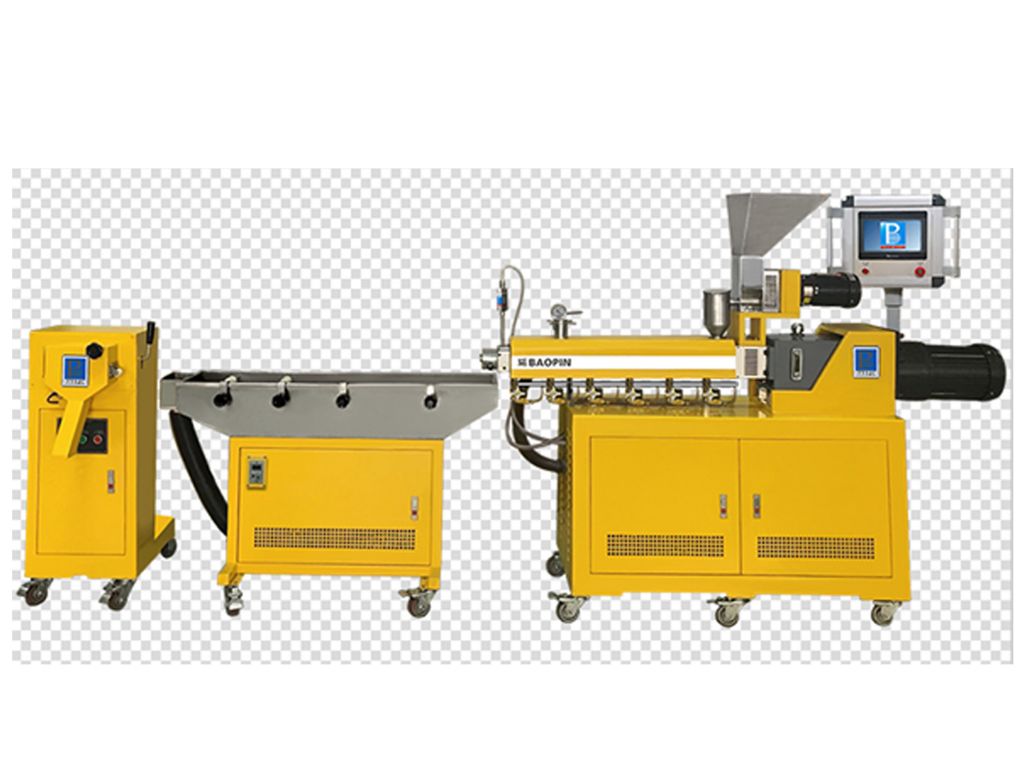

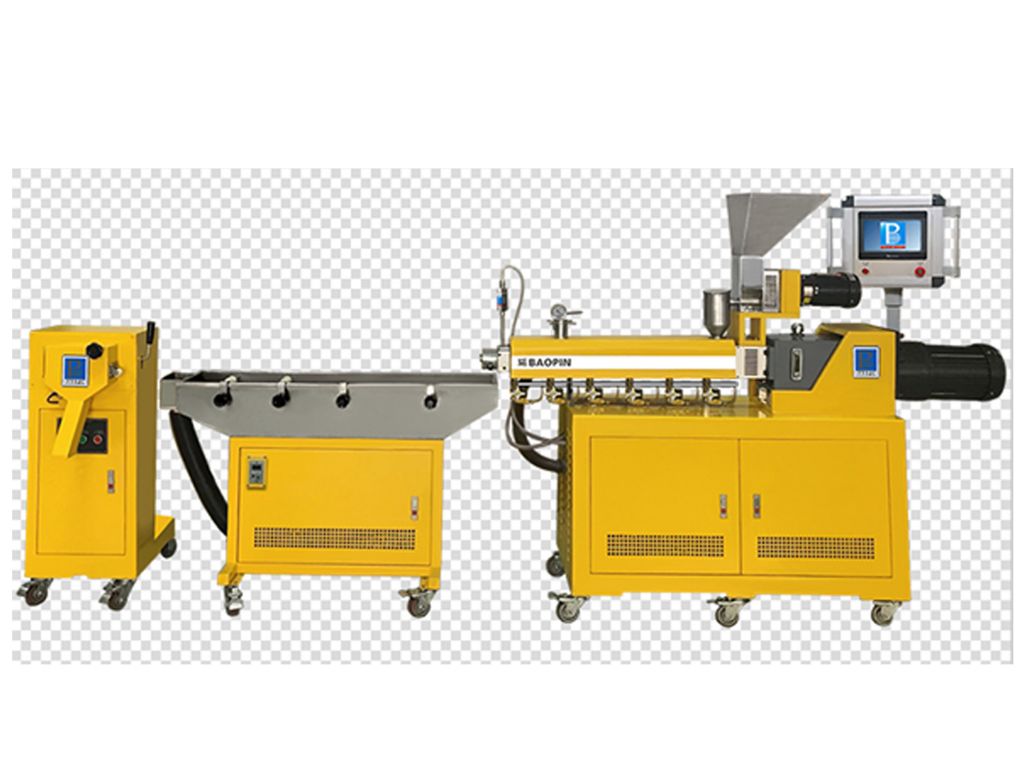

This lab twin screw plastic

extrusion machine consists of transmission device,

extrusion device, heating and cooling system, electric

control system, etc. It is appropriate for the mixing processing experiment of engineering plastics, modified plastics, waste plastics and color masterbatch etc., suitable for all kinds of plastic extrusion granulation, plasticizing homogeneous, color proofing, filling modification, etc. Parameters Double-screw extruder

Water tank

Granulation device

Features Double- Screw Extruder 1.Output:According to the raw material formulation process 2.Screw direction:Parallel and same direction 3.Screw:Spindle with 40 CrNiMoA chromium molybdenum alloy tool steel, screw thread adopts W6Mo5CR4V2 wear-resisting alloy steel, hardness is HRC60,with transportation, mixing, shearing, mixer, kneading and reflux block, building block series components, can combine according to any material recipe, to meet the needs of different extrusion process. 4.Barrel:5 sections of cylinder adopt 38 CrMoAlA nitriding steel forgings, liner wear-resistant alloy, hardness is HRC60, via nitriding, conditioning and ultra fine grinding process, the surface roughness Ra≤0.4μm, wear-resisting and corrosion resistance. 5.Heating zone:5 cast aluminum heaters fixed at barrel,1 heater at handpiece, each section with 1 kw heating power, security wind cowl overlied outside. 6.Cooling zone:Cylinder segment using soft water circulation cooling system, each segments of cooling water flow rate is adjustable, equipped with self-priming pump, 304 stainless steel water storage tank , water pipe and the electromagnetic valve component,etc. Can apply independent temperature control at each segments of cylinder. 7.Vacuum zone:Water circulation vacuum degassing device, equipped with water ring vacuum pumps, vacuum gauge, regulating valve components, forming non-clog exhaust system. 8.Feeding device:It adopts twin screw forced feeding with horizontal mixer. The feeding is even and stable, it is not easy to bridge, and the feeding speed is adjustable from 0-50rpm by frequency conversion. The feeder is slidably connected to the host to facilitate cleaning of the screw. 9.Die-head pressure:Handpiece working pressure is 15 mpa, high presicion temperature and pressure sensors monitor the nose melt temperature and pressure variation, interlock control host operation, with the overpressure protection function. 10.Granulation die head:38CrMoAlA chromium molybdenum alloy head, nitriding hardness HRC60, strand quantity and granulation diameter can be chosen, built-in hinge device can replace the screen rapidly. 11.Reduction gearbox:High speed heavy hard teeth surface gear transmission, gear reduction and torque distribution box is integration structure, internal transmission parts adopt imported bearing and oil seal, oil splash lubrication. 12.Drive motor:Precision heavy geared motor, constant torque power output control. Contact information Whatsapp: +86 18938261793 Email:      Company profile Dongguan Baopin Precision Instrument Co., Ltd. is the earliest manufacturer of experimental two roll mill and hydraulic press machine in China; it has over 25 years of experience. In the plastic material and polymer material industry, Baopin Technology's rich product line covers all processing research areas, especially in the polymer new material application industry. Many of our scientific research technologies are in the leading position in China. Baopin Technology has won more than 30 national patent technologies, its products have passed the EU CE certification, and passed the ISO9001:2015 quality management system certification. It is a high-tech enterprise recognized by the state. Baopin Technology adheres to the business philosophy of quality; integrity; innovation, and works together with users to create a better future. |

| بلد: | China |

| نموذج رقم: | BP-8177-ZB |

| سعر فوب: | 8000 ~ 49200 / Set أحصل على آخر سعر |

| الموقع: | China |

| سعر الحد الأدنى للطلب: | 8000 per Set |

| الحد الأدني للطلب: | 1 Set |

| تفاصيل التغليف: | Plywood Wooden Case |

| موعد التسليم: | 20 days |

| القدرة على التوريد: | 100 Set per Month |

| نوع الدفع: | Other, PayPal, Western Union, T/T |

| مجموعة المنتج : | laboratory twin screw extrusion line |