Description

1.Description

of the machine

1.Description

of the machine

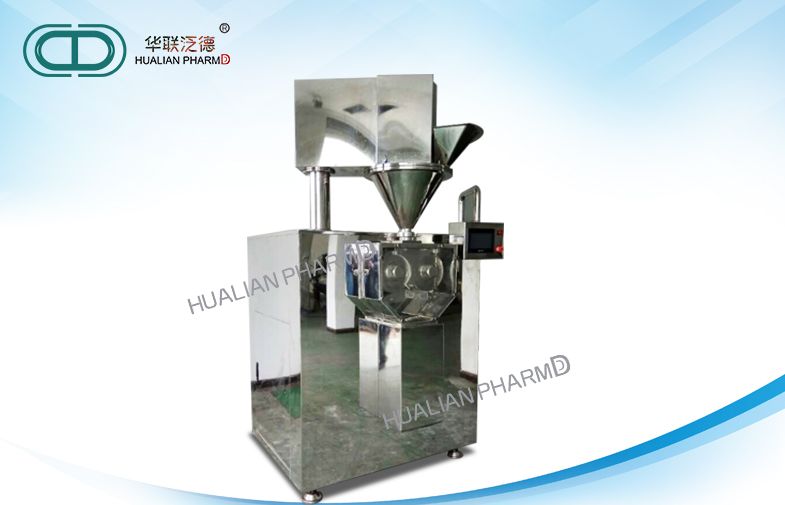

This is new equipment to make granules directly from the target

materials with some crystal water. The output granules can be used

for filling capsules, dissolved medicines, etc. The machine is

driven by VFD, with simple construction, stable working

performance, easy cleaning and convenient maintenance.

2. Function and fields of application

Widely applied in the pharmacy, foodstuff industry, chemical

industry, etc. Especially for some products which is practicable

for granulating by wet granulation.

3.Working principle:

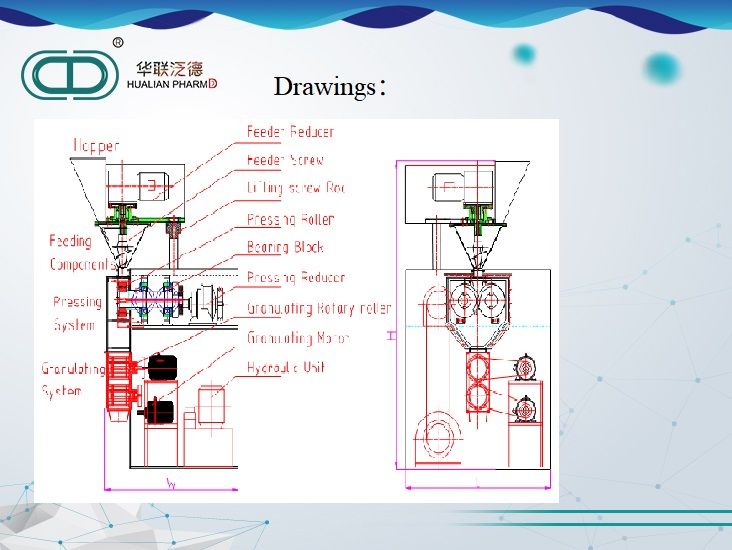

The machine is used to make granule output products directly by the

dry powder raw materials. The machine is using compression roller

to compressing the raw powder materials into sheet first, and then

crushing the sheet into pieces, finally granulating into the

granule output products.

4. Properties&Specialty:

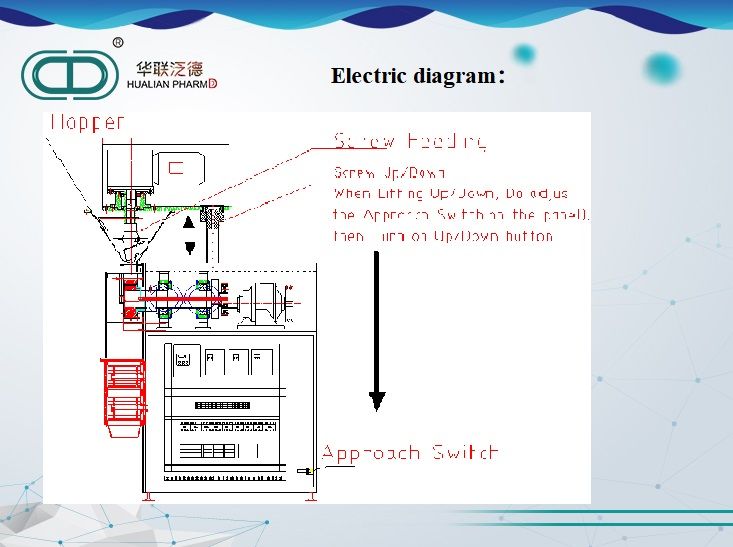

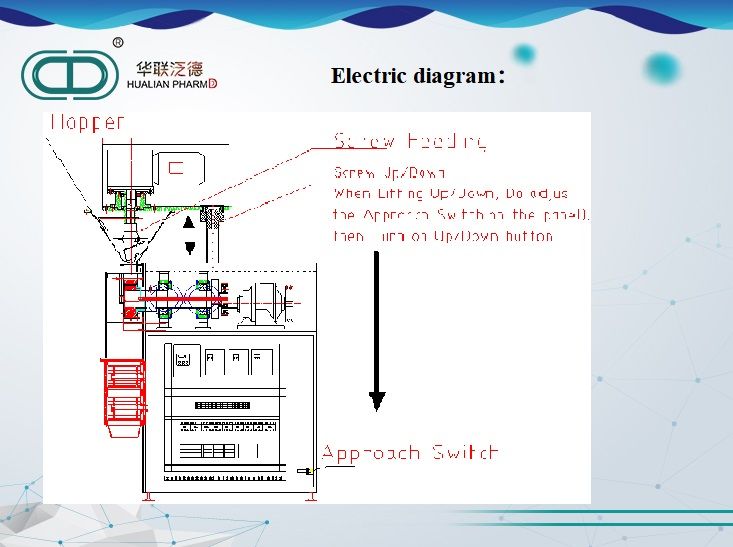

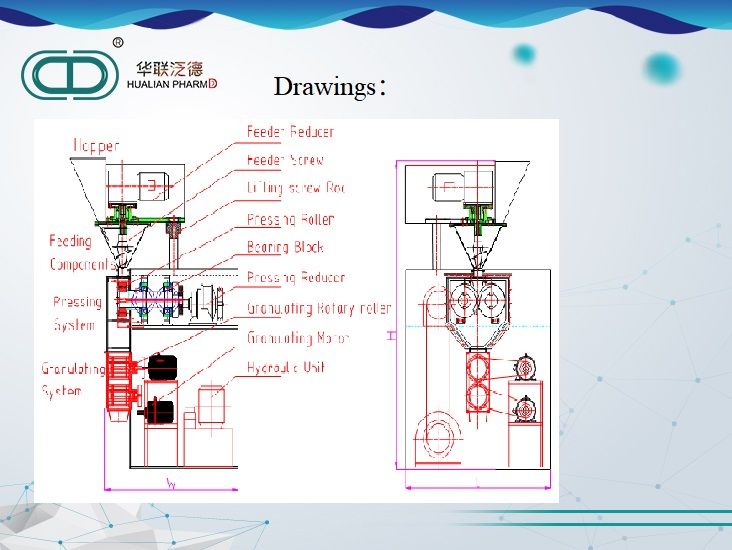

The machine is equipped with lifting components, downward feeding,

sheet pressing, granulating, hydraulic system, cooling components,

shell casing, controlling system, etc.

1). Lifting function powered by hydraulic, while feeding and sheet

pressing powered by VFD.

2). The hardness of pressed sheet determined by feeding speed,

pressure of oil cylinder and speed of pressing roller, they are

complementary effects, can be pre-set, set into best status.

3). The output size can be adjusting by changing mesh sieve.

4). Pressure of oil cylinder can be adjusted according to different

raw material products processing.

5). Cooling by tap-water or chilled water, which used for

compulsively cooling the over heat produced by the pressing

process.

6). Equipped with touch screen for the controlling part, with easy

operation, and low fault rate.

7). External pressing roller components are available to be

dismantled for cleaning. Feeding screws can be taken out after

dismantling the hopper.

1.Description

of the machine

1.Description

of the machine