FOB Price

أحصل على آخر سعر( Negotiable )

|Minimum Order

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

standard wooden case

Delivery Time:

20 WORKING DAYS

Supplying Ability:

200 Set per Month

Payment Type:

D/A, L/C, T/T

الشخص الذي يمكن الاتصال به Mr. Aston

zhangjiagang, Suzhou, Jiangsu

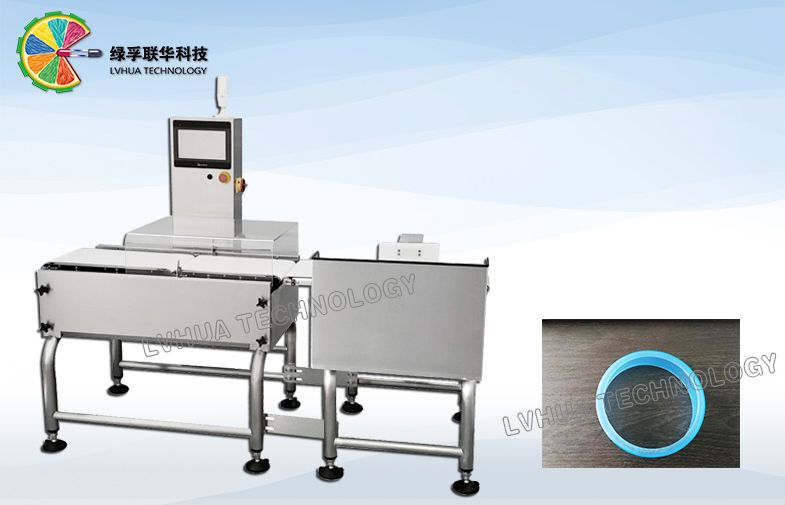

Stainless Steel Check Weigher Machine For Cosmetical Packaging Sachet Boxes EW 220

Technical Description

EW series check weighers are specifically designed for high demand

of weight accuracy, stability and intelligent operation. On bases

of core invention patents and patented self-adaptable algorithm,

plus with integrated circuits and high precision CNC structural

frame, EW series check weighers contribute the leading weight

inspection performance in the industry.

ã€Reputed

Components】

ã€Reputed

Components】

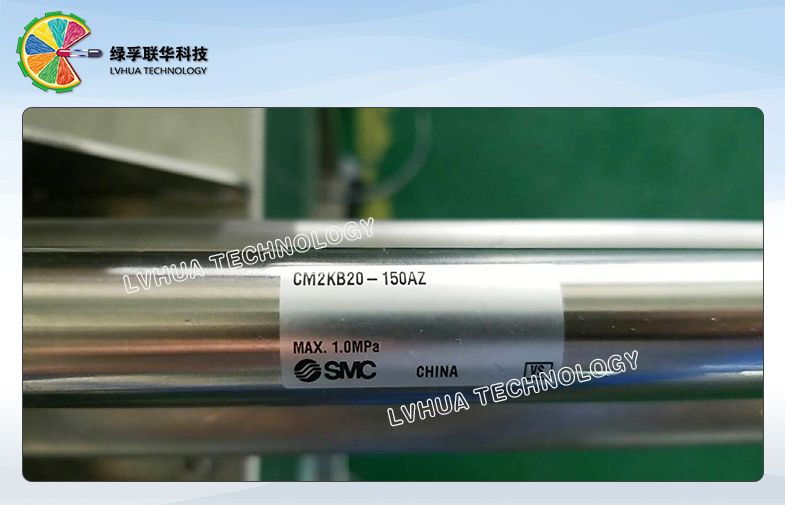

1. German HBM fast load cell

2. Danish Danfoss frequency converter

3. Japanese NTN roller bearings

4. US Gates synchronous belt

5. Touch screen Display

6. High precision structural components by CNC

7. Stainless steel 304 frame

ã€Advanced Technology】

1. German high-speed Load Cell with fast weighing speed.

2. FPGA hardware filter with intelligent algorithms, excellent processing speed weighing.

3. Intelligent self-learning technology, automatic weighing parameter settings, simple to set up.

4. Ultra-fast dynamic weight tracking and automatic compensation technology effectively.

Improve the detection of stability.

5. Based on the full touch screen friendly user interface, easy to operate.

6. With product presets, easy to edit and switching

7. With high capacity weighing logging feature, able to trace and output data interface

8. CNC machining of structural components, excellent dynamic stability

9 .304 stainless steel frame, strong and durable.

3.

Product Specifications

3.

Product Specifications

| Index | Parts | Description |

| 1 | Material of Frame | SUS304 |

| 2 | Weighing range (g) | 3~1000 |

| 3 | Minimum scale (g) | 0.1 |

| 4 | Accuracy (g) | ±0.3 |

| 5 | Max throughput (pcs/min) | 80 |

| 6 | Parameter setting | Auto setting by intelligent product study |

| 7 | Width of weighing belt mm | 220 |

| Length of weighing belt mm | 250or350or450 | |

| 8 | Height of conveyor belt (mm) | 700-820/780-900 |

| 9 | Direction of throughput | From left to right when facing control panel |

| 10 | Alarm mode | Aural and visual |

| 11 | Reject device | Air Jet/Air Pusher/Flipper/Drop Belt |

| 12 | Power | AC220-240V 1Phase, 300W |

| 13 | Working environment | Free of obvious vibration and air flow |

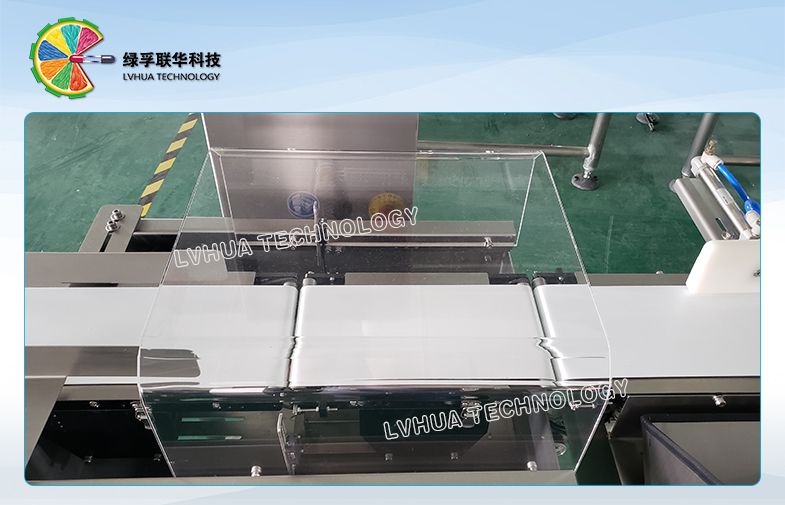

4. detailed picture: